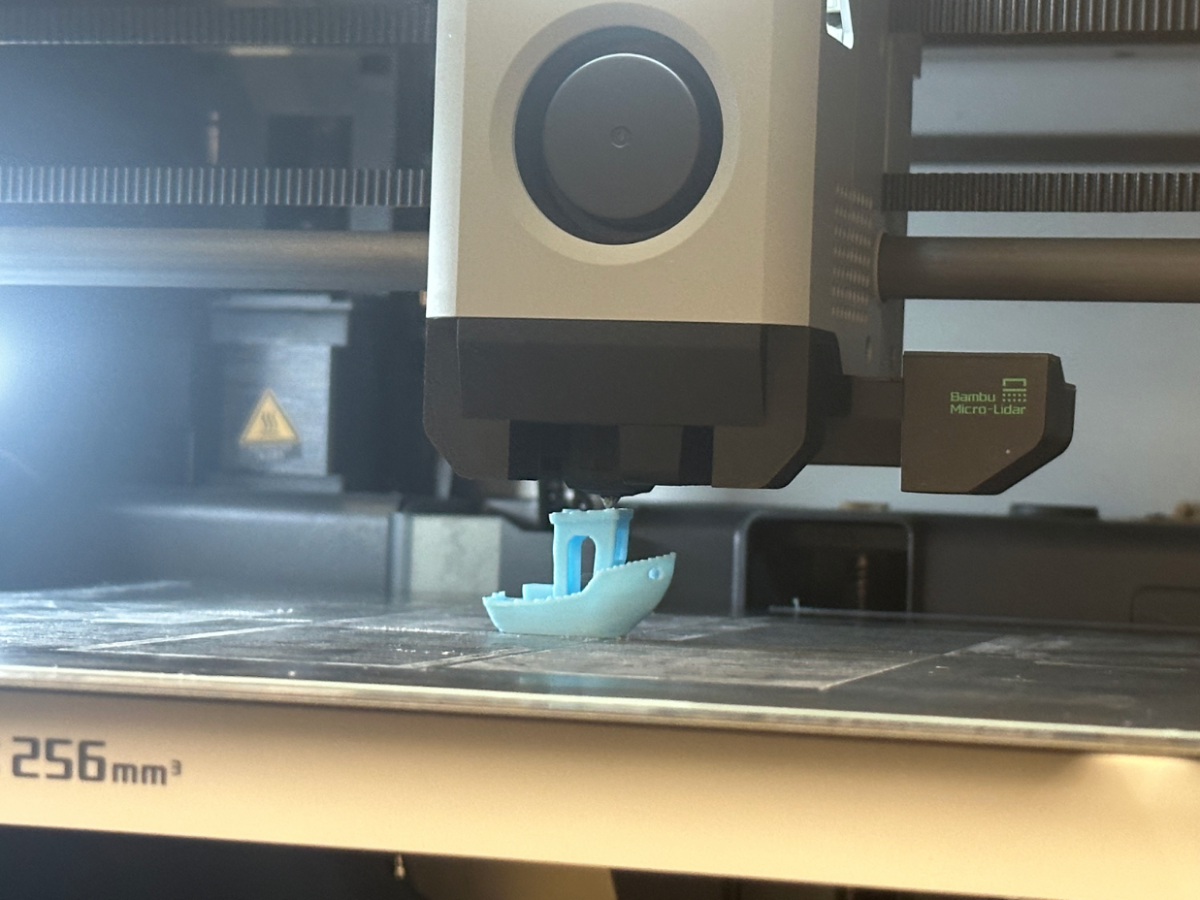

The Speed Boat challenge hosted by Studio 231 on March 7 unfortunately never left the dock, as a lack of attendees canceled the event.

The event description read “Join Studio 231 for an overview on how to improve your 3D prints so you can make the best prototypes possible. Attendees will then take part in a “Speedboat Challenge” where they will compete to see who can prepare the fastest print.”

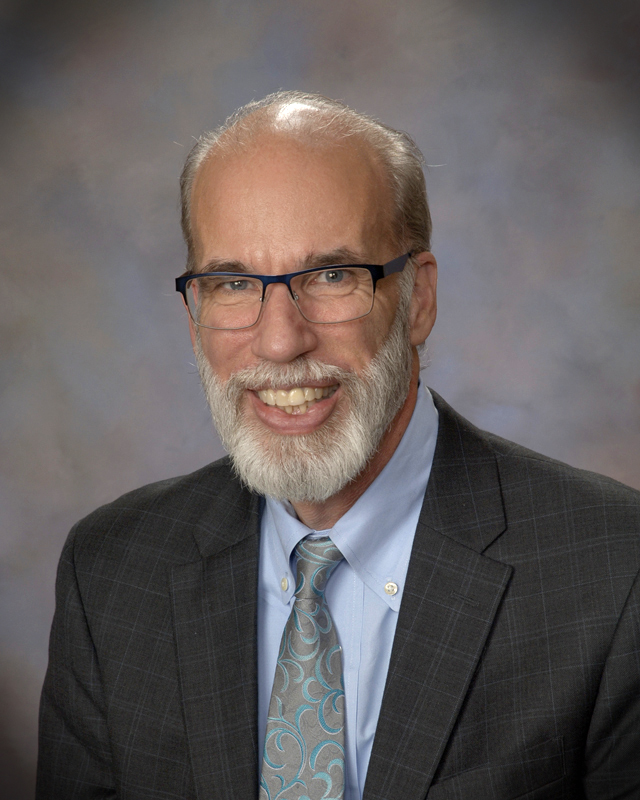

Perhaps the most important factor was that it began at 9:30 a.m. In a 2018 study, professors Chad Cotti (University of Wisconsin Oshkosh), John Gordanier (University of South Carolina), and Orgul Ozturk (University of South Carolina) found that the later a university class begins, the higher the grades of the students. Whether this correlated to the low attendance amongst entrepreneurship & engineering students or not, Studio 231 was disappointed, but not disheartened.

The benefits of the lab are immense according to lab supervisor Addison Deckert.

“Interacting with the studio is extremely valuable,” Deckert said. “It allows people to practice the entrepreneurial mindset, innovating, designing things, bringing things from step one all the way to your final product.”

Studio 231 is open to all students, staff, and faculty and is located on the second floor of the Business Hall.

In addition to an arsenal of 3D printers, the lab has a “cricket” which can cut vinyl, fabric, cardstock, and leather, and is nicknamed a “smart pair of scissors” according to Vince Gallo, a Studio 231 lab technician and senior mechanical engineering major.

“That’s pretty cool because someone can go in, make something on Canva and send it over to the machine and make 20 stickers in like five minutes,” Gallo said.

They also have a laser cutter that can etch engraving into wood boxes or signs, and circuit boards and wires to stay up to speed with their technological skills.

Both Deckert and Gallo agreed that their favorite project was constructing a prosthetic leg for a baby goat.

“It was really cool doing something for a live animal that was actually helping its quality of life,” Deckert said. “We worked pretty closely with the vet school on that.”

The students were able to complete the project, despite having minimal knowledge on the subject in the beginning.

“We somehow made rear hind legs for this goat in the span of like a month and a half, which is really impressive,” Gallo said. “That was quite the experience since none of us know that much about prosthetics or goats.”

As students and staff come and go with requests for T-shirts, stickers, and whatever 3D creations they need, it can feel rewarding for the technicians.

“It’s cool to help students out in that way, and help them present themselves in a good way for either investors or their professors,” Gallo said.

With that being said, some ideas are built differently than others and present a unique challenge to the studio.

“Sometimes people’s ideas are so grandiose that there isn’t one clear way on how to make it,” Deckert said. “Sometimes you’re unsure if this should be 3D printed or laser cut and how to exactly help their idea come to physical form. I think that’s the hardest part of being a lab technician is we have to figure out the technical side of these grand ideas.”

Although there were no tiny boat races, Studio 231 appears to be floating just fine.

For comments/questions about this story DM us on Instagram @thewhitatrowan or email [email protected]

!["Working with [Dr. Lynch] is always a learning experience for me. She is a treasure,” said Thomas. - Staff Writer / Kacie Scibilia](https://thewhitonline.com/wp-content/uploads/2025/04/choir-1-1200x694.jpg)